The proliferation of multifunction and high-performance electronics has been growing rapidly in areas such as mobile devices and car electronics. However, because these products tend to have short life cycles, production equipment that has the flexibility to respond to ramping up to mass production in a short amount of time and changes in demand is sought after.

Configure lines according to the purpose

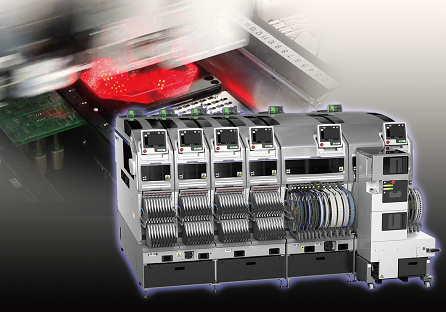

Modules, heads, and supply units can be combined freely, so that the optimum line configuration can always be built by changing the configuration to match changes in the part type and product model.

It is possible to expand the capability only for the necessary level by adding modules and exchanging units.

Offline maintenance to maximize production uptime

Because swapping units that require maintenance with units that are fully maintained can be performed at the operator level, downtime can also be greatly reduced. Maintenance can be performed offline on the removed units while production is still running.

The machines are designed to reduce operator work load

The module can be pulled forward for easy access inside the machine from both sides. Working at the machine can be performed in a safe and comfortable posture.

Heads, nozzles, and feeders are all managed by ID.

Detailed production data for materials and equipment is stored in the database, to be used for line management, maintenance management, and traceability.

The operator simply pushes the START button after exchanging the head. Heads are calibrated automatically in the machine so that production can resume.

Heads can be exchanged easily

Heads can be exchanged easily without tools.

The heads are lightweight and thus can be removed easily by a machine operator when needing to perform maintenance or troubleshooting when responding to issues.

High speed and high accuracy

Having compact and lightweight heads reduced the load on the machine. As a result, the modules themselves are able to be compact while maintaining high speed and high accuracy.

The NXT III is a modular SMT mounter that is able to provide the best line every time for factories that have such kinds of frequent changes for producing electronics devices.

NXT Concept

Full modularization and unitization

ID management

Automatic calibration

Features

Compact lightweight heads